REQUIREMENTS

- Windows Versions (64-bit): Windows 11, Windows 10

- Application is available only in 64-bit version.

DOWNLOADS

CT-Mechanical

Version 2.0

Computational software to analyze and determine the cooling capability and performance of mechanical draft cooling towers (counterflow and crossflow, induced and forced draft).

All calculations are performed employing accurate numerical techniques implementing some of the most precise mathematical models for the properties of humid air, water and steam developed for industrial purposes.

- Mechanical Draft Cooling Towers.

- Demand Curves.

- Merkel Number.

- Psychrometrics Calculator.

Mechanical Draft

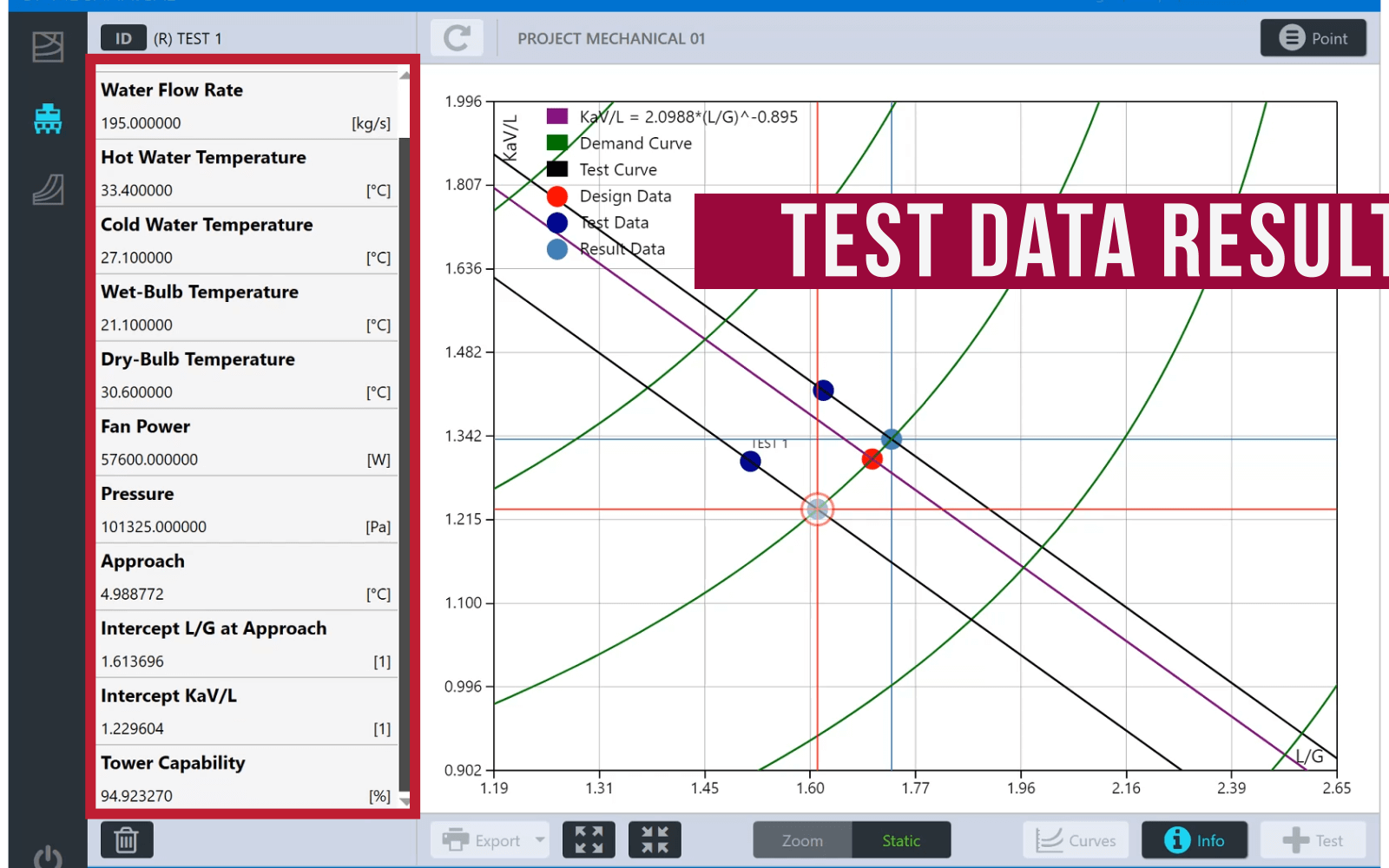

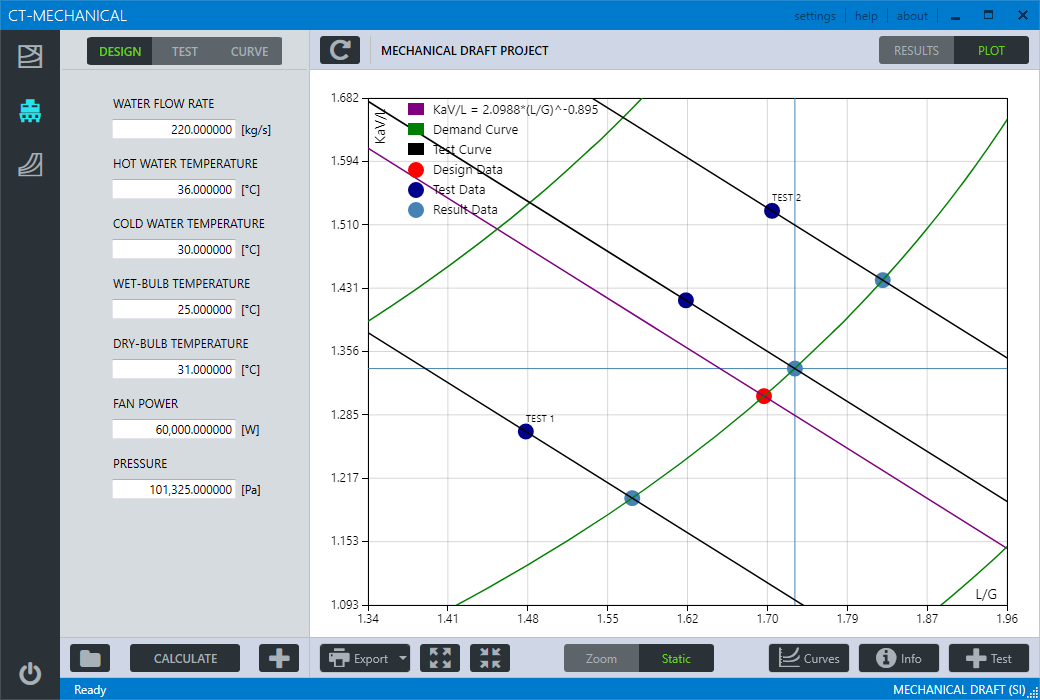

Numerical calculation and graphical display of performance and thermal capability based on the Acceptance Test Code CTI ATC-105 using the characteristic curve method for mechanical draft cooling towers (counterflow and crossflow, induced and forced draft).

- Evaluation of the performance of mechanical draft cooling towers based on the Acceptance Test Code CTI ATC-105 from test data points using the characteristic curve method.

- Calculation of tower cooling capability for each data test added to a project.

- Calculation and graphical display of demand curves following the integration of Merkel´s equation.

- Complete validation of input variables, informing the user of the correct range of variables for a valid test data calculation.

- Creation of projects in a database that describe a particular set of design and test input data together with the calculated demand curves, test data and results for later retrieval or recalculation.

- Generation of high-quality pdf files of demand curve plots and the corresponding design, test and result points for a particular project.

- Generation of excel and pdf files of numerical results of data tests.

- Supports input variables and calculation results in SI (metric) and I-P (English) system of units.

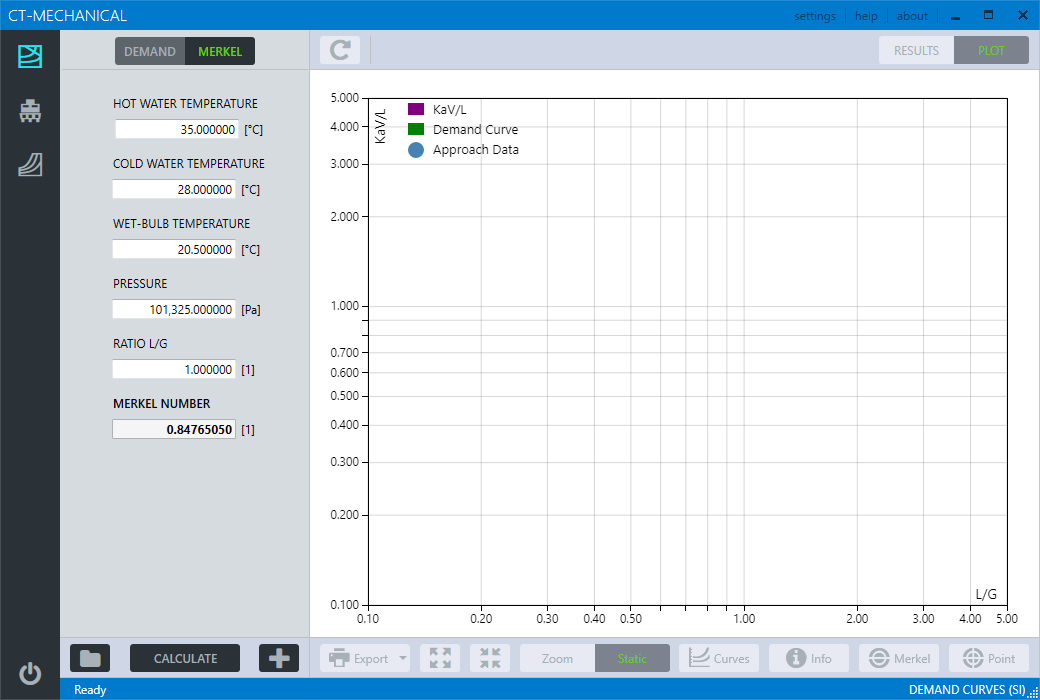

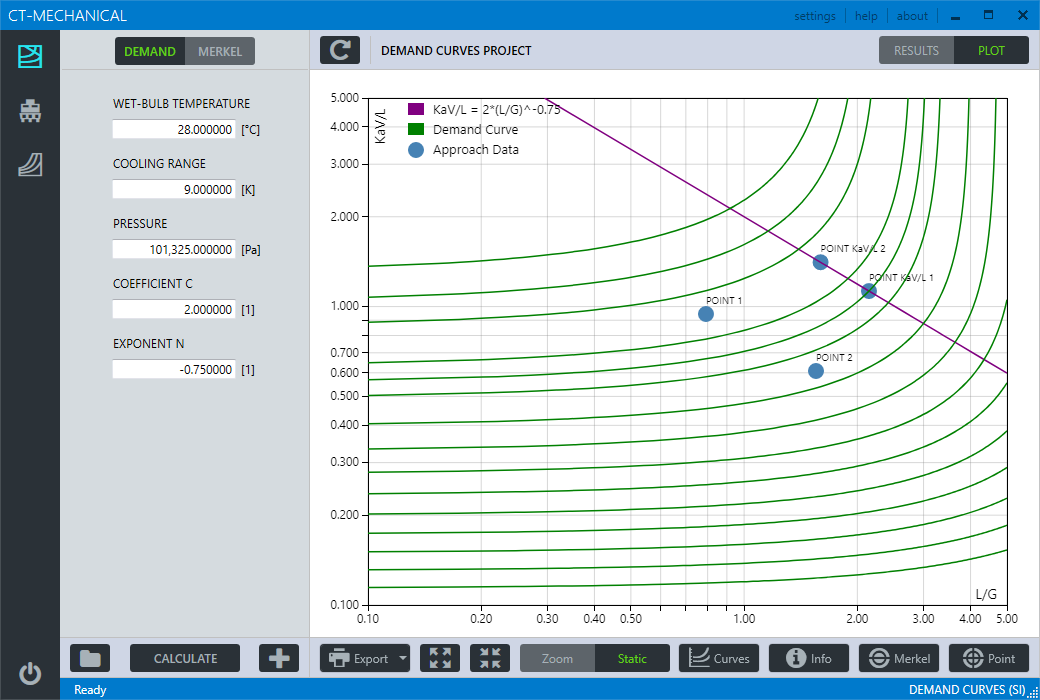

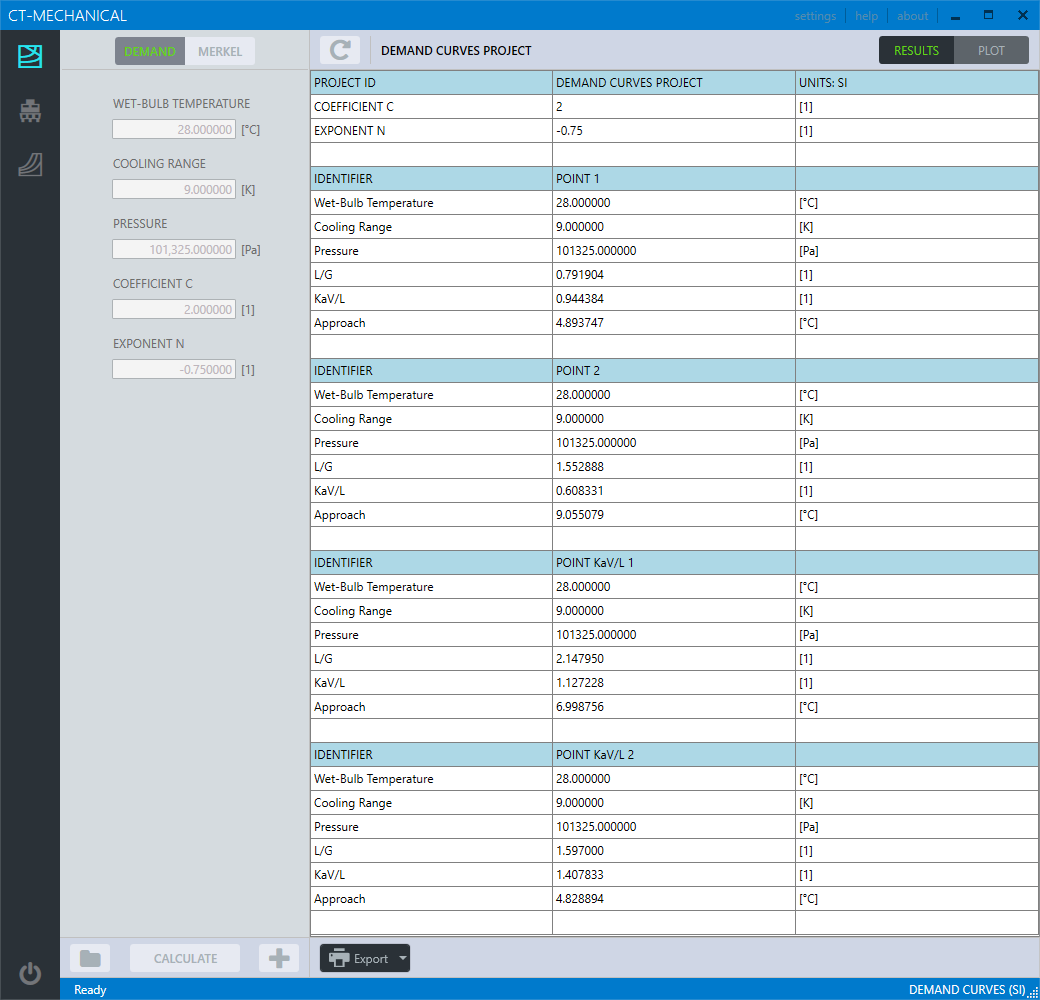

Demand Curves

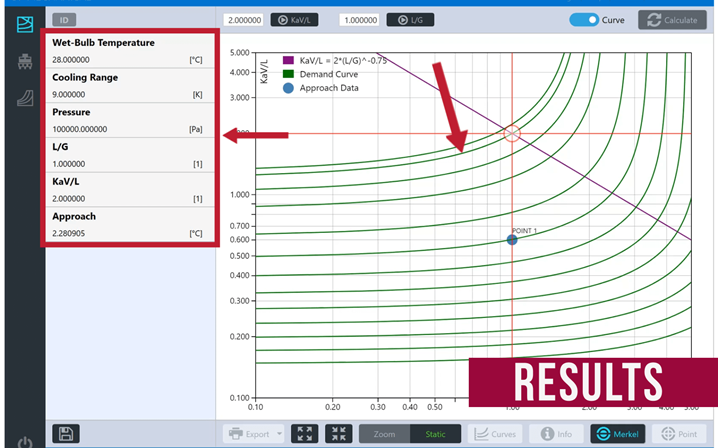

Numerical calculation and graphical display of demand curves and approach data points.

- Calculation and graphical display of demand curves following the integration of Merkel´s equation.

- Calculation and graphical display of approach data points.

- Complete validation of input variables.

- Creation of projects in a database that describe a particular set of input variables together with the calculated demand curves and approach data points for later retrieval or recalculation.

- Generation of high-quality pdf files of demand curve plots.

- Generation of excel and pdf files of approach data point calculations results.

- Supports input variables and calculation results in SI (metric) and I-P (English) system of units.

Merkel Number

Numerical calculation of Merkel number using the Chebyshev numerical method.

- Calculation of Merkel number using the Chebyshev numerical method.

- Complete validation of input variables, informing of the correct range of variables for a valid calculation.

- Supports input variables and calculation results in SI (metric) and I-P (English) system of units.

Psychrometrics Calculator

A psychrometrics calculator based on the latest mathematical models to numerically evaluate the properties of humid air, water, steam and ice.

- Calculation of 42 properties of humid air, water, steam, ice and psychrometrics.

- It allows for 17 combinations of two thermodynamic properties to be entered as input parameters.

- Complete validation of input thermodynamic properties, it calculates and provides the user with information about the appropriate input values in the valid range of computations.

- Supports input variables and calculation results in SI (metric) and I-P (English) system of units.

Introduction

Mechanical Draft allows the evaluation of the performance capability of mechanical draft cooling towers based on the Acceptance Test Code CTI ATC-105 from test data points using the characteristic curve method.

By determining design and test conditions for a particular mechanical draft cooling tower, the manufacturer´s characteristic curve parameters and a design liquid to gas ratio (L/G), Mechanical Draft calculates the cooling capability at design conditions, plotting in a log-log graph each of the input data conditions as well as the resulting intercept results (denoted as a result data) given as a pair of values determined by KaV/L and L/G in the SI and I-P system of units.

Mechanical Draft solves the energy equation by integrating the Merkel equation numerically using the four-point Chebyshev numerical method employing the following models for the calculation of water and air properties:

Properties of Water and Steam

- Formulations from the IAPWS (International Association for the Properties of Water and Steam) IAPWS-IF97 Industrial formulation (Revision 2007) and related models.

Properties of Humid Air

- Thermodynamic and psychrometric property algorithms from the ASHRAE Research Project 1485.

- Scientific Formulation IAPWS-95, IAPWS Formulation 2008 and IAPWS Formulation 2006. Properties of dry air are from the NIST Reference equation of Lemmon et al.

Graphical User Interface

| Input Variable | Definition |

|---|---|

| WATER FLOW RATE | Quantity of hot water flowing into the tower. |

| HOT WATER TEMPERATURE | Temperature of inlet water. |

| COLD WATER TEMPERATURE | Average temperature of the cold water basin discharge (outlet). |

| WET-BULB TEMPERATURE | Temperature of air wet-bulb entering the cooling tower. |

| DRY-BULB TEMPERATURE | Temperature of air dry-bulb entering the cooling tower. |

| FAN POWER | Power input to the fan drive assembly, excluding power losses in the driver. |

| PRESSURE | Total pressure referred to atmospheric. |

| COEFFICIENT C | Constant defined for a particular packing design. |

| EXPONENT N | Exponent defined for a particular packing design. |

| DESIGN L/G RATIO C | Ratio of water flow rate to airflow rate at design. |

| TOWER TYPE | $Forced$ draft: fan located near the bottom, forcing the air from bottom to top. $Induced$ draft: fan located at the top inducing suction from the tower and discharging it into the atmosphere. |

Range of Input Variables

| Property | Range in SI Units | SI Units |

|---|---|---|

| WATER FLOW RATE | 0.5 ≤ Flow ≤ 100000.0 | kg/s |

| HOT WATER TEMPERATURE | 1.0 ≤ T ≤ 90.0 | °C |

| COLD WATER TEMPERATURE | 1.0 ≤ T ≤ 90.0 | °C |

| WET-BULB TEMPERATURE | 1.0 ≤ T ≤ 90.0 | °C |

| DRY-BULB TEMPERATURE | 1.0 ≤ T ≤ 90.0 | °C |

| FAN POWER | 1.0 ≤ Fan ≤ 1.0E6 | W |

| PRESSURE | 60000 ≤ P ≤ 110000 | Pa |

| COEFFICIENT C | 1.0 ≤ C ≤ 3.0 | 1 |

| EXPONENT N | -2.0 ≤ N ≤ -0.1 | 1 |

| DESIGN L/G RATIO | 0.1 ≤ L/G ≤ 5.0 | 1 |

| KaV/L | 0.1 ≤ KaV/L ≤ 5.0 | 1 |

| L/G | 0.1 ≤ L/G ≤ 5.0 | 1 |

| APPROACH | 1.0 ≤ T ≤ 60.0 | °C |

| Property | Range in I-P Units | I-P Units |

|---|---|---|

| WATER FLOW RATE | 7.92 ≤ Flow ≤ 1585032.22 | gpm |

| HOT WATER TEMPERATURE | 33.8 ≤ T ≤ 194.0 | °F |

| COLD WATER TEMPERATURE | 33.8 ≤ T ≤ 194.0 | °F |

| WET-BULB TEMPERATURE | 33.8 ≤ T ≤ 194.0 | °F |

| DRY-BULB TEMPERATURE | 33.8 ≤ T ≤ 194.0 | °F |

| FAN POWER | 0.001342 ≤ Fan ≤ 1341.022 | bhp |

| PRESSURE | 8.702264 ≤ P ≤ 15.954151 | psia |

| COEFFICIENT C | 1.0 ≤ C ≤ 3.0 | 1 |

| EXPONENT N | -2.0 ≤ N ≤ -0.1 | 1 |

| DESIGN L/G RATIO | 0.1 ≤ L/G ≤ 5.0 | 1 |

| KaV/L | 0.1 ≤ KaV/L ≤ 5.0 | 1 |

| L/G | 0.1 ≤ L/G ≤ 5.0 | 1 |

| APPROACH | 1.0 ≤ T ≤ 140.0 | °F |

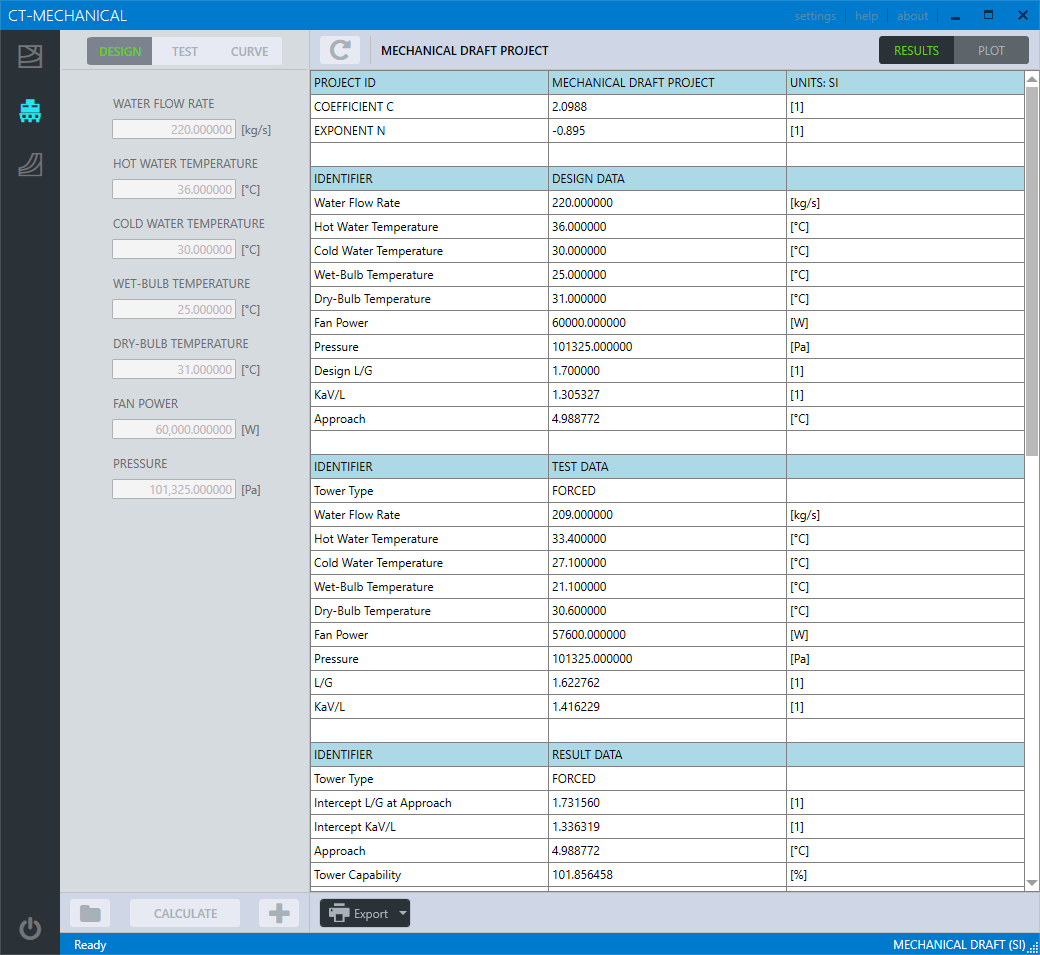

Calculation Results

| Result Variable | Definition |

|---|---|

| APPROACH | Approach calculated at design data. |

| INTERCEPT L/G AT APPROACH | Value of L/G ratio calculated at result point (L/G value of the intersection of the demand curve calculated on the approach at design and the curve parallel to the characteristic curve defined on the test point). |

| INTERCEPT KaV/L | Value of KaV/L ratio calculated at result point (KaV/L value of the intersection of the demand curve calculated on the approach at design and the curve parallel to the characteristic curve defined on the test point). |

| TOWER CAPABILITY | Cooling capability result calculated for a data test. |

Merkel Number

Introduction

An evaporative cooling tower is a device that is used to remove waste heat from the water used in an industrial process equipment or a machinery by rejecting that waste heat into the environment. When water is mixed with air in a cooling tower configuration, a heat transfer process takes places that involves a latent heat transfer due to the vaporization of a small amount of water and a sensible heat transfer reflecting the difference in temperatures of water and air.

Based on the theory developed by Merkel, the heat transfer process that occurs in a cooling tower by considering the enthalpy potential difference as the driving force is described by the Merkel equation:

| $\frac{{KaV}}{L} $ | $=$ | Tower characteristic | |

| $T{}_1 $ | $=$ | Hot water temperature (inlet) | |

| $T{}_2 $ | $=$ | Cold water temperature (outlet) | |

| $h' $ | $=$ | Enthalpy of saturated air at water temperature | |

| $h $ | $=$ | Enthalpy of main airstream | |

| ${c_{pw}}$ | $=$ | Specific heat capacity of water | |

| $d{T_w}$ | $=$ | Temperature differential of water |

The Merkel Number application solves the equation (1) numerically using the four-point Chebyshev numerical method employing the following models for the calculation of water and air properties:

Properties of Water and Steam

- Formulations from the IAPWS (International Association for the Properties of Water and Steam) IAPWS-IF97 Industrial formulation (Revision 2007) and related models.

Properties of Humid Air

- Thermodynamic and psychrometric property algorithms from the ASHRAE Research Project 1485.

- Scientific Formulation IAPWS-95, IAPWS Formulation 2008 and IAPWS Formulation 2006. Properties of dry air are from the NIST Reference equation of Lemmon et al.

Graphical User Interface

Range of Input Variables

| Property | Range in SI Units | SI Units |

|---|---|---|

| HOT WATER TEMPERATURE | 1.0 ≤ T ≤ 90.0 | °C |

| COLD WATER TEMPERATURE | 1.0 ≤ T ≤ 90.0 | °C |

| WET-BULB TEMPERATURE | 1.0 ≤ T ≤ 90.0 | °C |

| PRESSURE | 60000 ≤ P ≤ 110000 | Pa |

| RATIO L/G | 0.01 ≤ L/G ≤ 5.0 | 1 |

| Property | Range in I-P Units | I-P Units |

|---|---|---|

| HOT WATER TEMPERATURE | 33.8 ≤ T ≤ 194.0 | °F |

| COLD WATER TEMPERATURE | 33.8 ≤ T ≤ 194.0 | °F |

| WET-BULB TEMPERATURE | 33.8 ≤ T ≤ 194.0 | °F |

| PRESSURE | 8.70226426 ≤ P ≤ 15.95415115 | psia |

| RATIO L/G | 0.01 ≤ L/G ≤ 5.0 | 1 |

Demand Curves

Introduction

Demand Curves allows to calculate and plot in a log-log graph isolines resulting from the integration of equation (1) using as a parameter an approach value. It also calculates the approach given a pair of values determined by KaV/L and L/G, both in the SI and I-P system of units. The definition of the input variables for calculation of the demand curves is given in Table X.

For a specific tower, there is a characteristic curve in the form of a plot of tower characteristic, $KaV/L$, versus water to air flow ratio, $L/G$. This plot is described with an equation of the following form:

Graphical User Interface

| Input Variable | Definition |

|---|---|

| WET-BULB TEMPERATURE | Temperature of air wet-bulb entering the cooling tower |

| COOLING RANGE | Difference between hot water temperature and cold water temperature |

| PRESSURE | Total pressure referred to atmospheric |

| COEFFICIENT C | Constant defined for a particular packing design |

| EXPONENT N | Exponent defined for a particular packing design |

Range of Input Variables

| Property | Range in SI Units | SI Units |

|---|---|---|

| WET-BULB TEMPERATURE | 1.0 ≤ T ≤ 90.0 | °C |

| COOLING RANGE | 0.1 ≤ T ≤ 90.0 | °C |

| PRESSURE | 60000 ≤ P ≤ 110000 | Pa |

| COEFFICIENT C | 1.0 ≤ C ≤ 3.0 | 1 |

| EXPONENT N | -2.0 ≤ N ≤ -0.1 | 1 |

| KaV/L | 0.1 ≤ KaV/L ≤ 5.0 | 1 |

| L/G | 0.1 ≤ L/G ≤ 5.0 | 1 |

| Approach | 1.0 ≤ T ≤ 60.0 | °C |

| Property | Range in SI Units | SI Units |

|---|---|---|

| WET-BULB TEMPERATURE | 33.8 ≤ T ≤ 194.0 | °F |

| COOLING RANGE | 0.1 ≤ T ≤ 162.0 | °F |

| PRESSURE | 8.70226426 ≤ P ≤ 15.95415115 | psia |

| COEFFICIENT C | 1.0 ≤ C ≤ 3.0 | 1 |

| EXPONENT N | -2.0 ≤ N ≤ -0.1 | 1 |

| KaV/L | 0.1 ≤ KaV/L ≤ 5.0 | 1 |

| L/G | 0.1 ≤ L/G ≤ 5.0 | 1 |

| Approach | 1.0 ≤ T ≤ 140.0 | °F |

Calculation Results

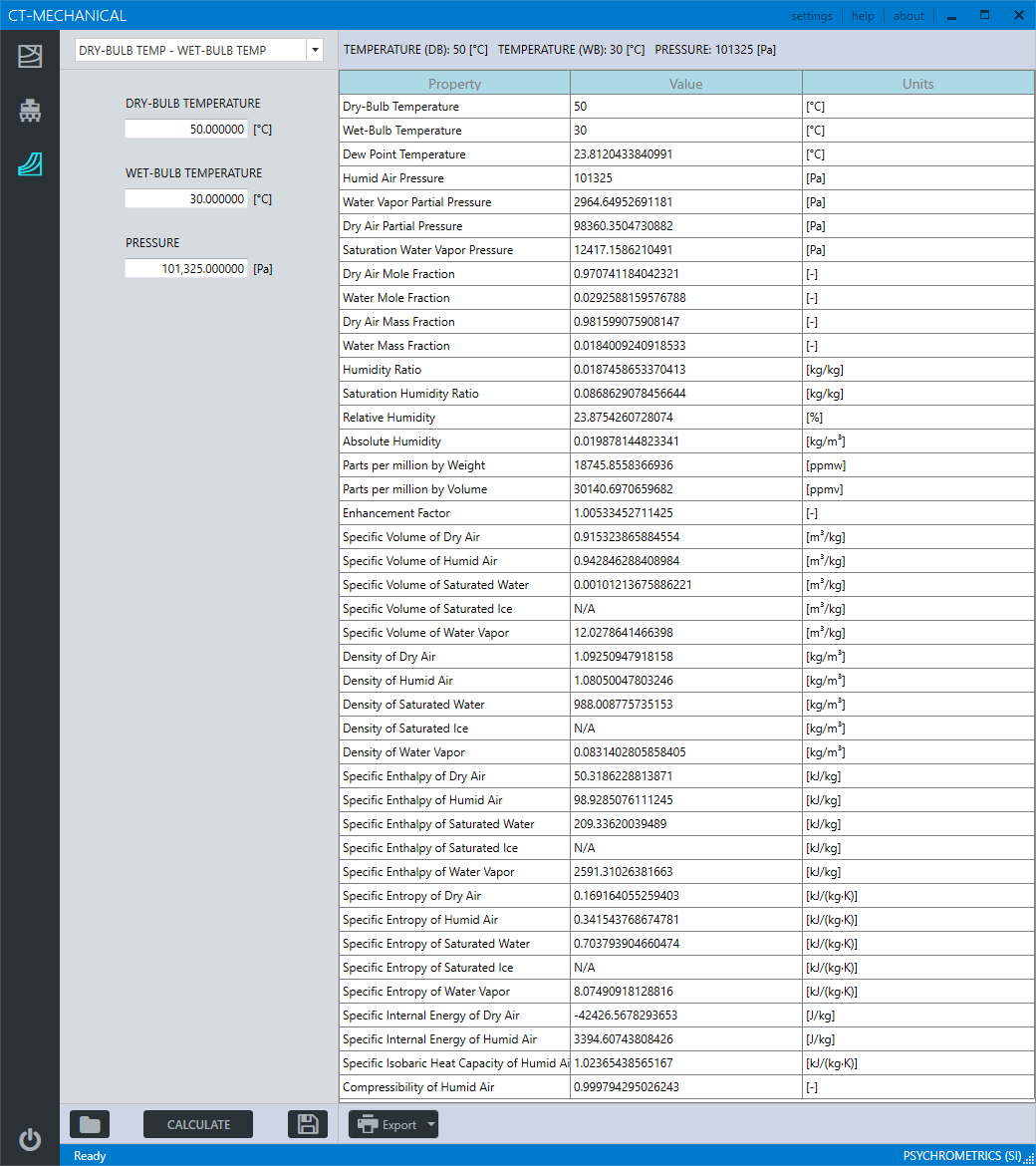

Introduction

Psychrometrics Calculator allows the calculation of physical properties of humid air, water, steam, ice and psychrometrics commonly used in the design and operation of cooling towers.

- Calculation of 42 properties of humid air, water, steam, ice and psychrometrics.

- Allows for 17 combinations of two thermodynamic properties to be entered as input variables:

-

- Dry-bulb Temperature / Wet-bulb Temperature

- Dry-bulb Temperature / Dew Point Temperature

- Dry-bulb Temperature / Relative Humidity

- Dry-bulb Temperature / Humidity Ratio

- Dry-bulb Temperature / Specific Enthalpy

- Dry-bulb Temperature / Specific Volume

- Wet-bulb Temperature / Dew Point Temperature

- Wet-bulb Temperature / Relative Humidity

- Wet-bulb Temperature / Humidity Ratio

- Dew Point Temperature / Relative Humidity

- Dew Point Temperature / Specific Enthalpy

- Dew Point Temperature / Specific Volume

- Relative Humidity / Humidity Ratio

- Relative Humidity / Specific Enthalpy

- Relative Humidity / Specific Volume

- Humidity Ratio / Specific Enthalpy

- Humidity Ratio / Specific Volume

- Supports input parameters and calculation results in both SI (metric) and I-P (english) system of units.

- For each combination of input thermodynamic variables, it calculates and provides the user with information about the appropriate values in the valid range of computations.

- Calculation results can be saved to a to a database for later retrieval.

- Calculation results can be exported to excel/pdf file formats.

Calculation of the properties of humid air, water, steam, ice and psychrometrics are based on the precision provided by the mathematical formulations of the following thermodynamic and transport properties models:

Properties of Water and Steam

- Formulations from the IAPWS (International Association for the Properties of Water and Steam) IAPWS-IF97 Industrial formulation (Revision 2007) and related models.

Properties of Humid Air

- Thermodynamic and psychrometric property algorithms from the ASHRAE Research Project 1485.

- Scientific Formulation IAPWS-95, IAPWS Formulation 2008 and IAPWS Formulation 2006. Properties of dry air are from the NIST Reference equation of Lemmon et al.

Graphical User Interface

Range of Input Variables

| Property | Range in SI Units | SI Units |

|---|---|---|

| DRY-BULB TEMPERATURE | -143.15 ≤ Tdb ≤ 350.0 | °C |

| WET-BULB TEMPERATURE | -143.15 ≤ Twb ≤ 350.0 | °C |

| DEW POINT TEMPERATURE | -143.15 ≤ Tdp ≤ 350.0 | °C |

| RELATIVE HUMIDITY | 0 .0 ≤ RH ≤ 100.0 | [%] |

| HUMIDITY RATIO | 0.0 ≤ W ≤ 10.0 | kg/kg |

| SPECIFIC ENTHALPY | -311.357 ≤ h ≤ 32135.848 | kJ/kg |

| SPECIFIC VOLUME | 1.469E-3 ≤ v ≤ 3.055E5 | m3/kg |

| PRESSURE | 10.0 ≤ P ≤ 10.0E6 | Pa |

| Property | Range in I-P Units | I-P Units |

|---|---|---|

| DRY-BULB TEMPERATURE | -225.67 ≤ Tdb ≤ 662.0 | °F |

| WET-BULB TEMPERATURE | -225.67 ≤ Twb ≤ 662.0 | °F |

| DEW POINT TEMPERATURE | -225.67 ≤ Tdp ≤ 662.0 | °F |

| RELATIVE HUMIDITY | 0 .0 ≤ RH ≤ 100.0 | [%] |

| HUMIDITY RATIO | 0.0 ≤ W ≤ 10.0 | lb/lb |

| SPECIFIC ENTHALPY | -126.174 ≤ h ≤ 13823.61 | Btu/lb |

| SPECIFIC VOLUME | 2.353E-2 ≤ v ≤ 4.893E6 | ft3/lb |

| PRESSURE | 0.00145 ≤ P ≤ 1450.4 | psia |

Calculation Results

| Property | SI Units | I-P Units |

|---|---|---|

| Dry-Bub Temperature | °C | °F |

| Wet-Bulb Temperature | °C | °F |

| Dew Point Temperature | °C | °F |

| Humid Air Pressure | Pa, kPa, bar, mmHg | psia, inHg, inH2O, atm |

| Water Vapor Partial Pressure | Pa, kPa, bar, mmHg | psia, inHg, inH2O, atm |

| Dry Air Partial Pressure | Pa, kPa, bar, mmHg | psia, inHg, inH2O, atm |

| Saturation Water Vapor Pressure | Pa, kPa, bar, mmHg | psia, inHg, inH2O, atm |

| Dry Air Mole Fraction | [-] | [-] |

| Water Mole Fraction | [-] | [-] |

| Dry Air Mass Fraction | [-] | [-] |

| Water Mass Fraction | [-] | [-] |

| Humidity Ratio | kg(w)/kg(da), g(w)/kg(da) | lb(w)/lb(da), gr(w)/lb(da) |

| Saturation Humidity Ratio | kg(w)/kg(da), g(w)/kg(da) | lb(w)/lb(da), gr(w)/lb(da) |

| Relative Humidity | [%] | [%] |

| Absolute Humidity | kg(w)/m3 | lb(w)/ft3 |

| Parts per million by weight | ppmw | ppmw |

| Parts per million by volume | ppmv | ppmv |

| Enhancement Factor | [-] | [-] |

| Specific Volume of Dry Air | m3/kg, cm3/g | ft3/lb, in3/lb |

| Specific Volume of Humid Air | m3/kg, cm3/g | ft3/lb, in3/lb |

| Specific Volume of Saturated Water | m3/kg, cm3/g | ft3/lb, in3/lb |

| Specific Volume of Saturated Ice | m3/kg, cm3/g | ft3/lb, in3/lb |

| Specific Volume of Water Vapor | m3/kg, cm3/g | ft3/lb, in3/lb |

| Density of Dry Air | kg/m3, g/cm3 | lb/ft3, lb/in3 |

| Density of Humid Air | kg/m3, g/cm3 | lb/ft3, lb/in3 |

| Density of Saturated Water | kg/m3, g/cm3 | lb/ft3, lb/in3 |

| Density of Saturated Ice | kg/m3, g/cm3 | lb/ft3, lb/in3 |

| Density of Water Vapor | kg/m3, g/cm3 | lb/ft3, lb/in3 |

| Specific Enthalpy of Dry Air | J/kg, kJ/kg | Btu/lb, ft lbf/lb |

| Specific Enthalpy of Humid Air | J/kg, kJ/kg | Btu/lb, ft lbf/lb |

| Specific Enthalpy of Saturated Water | J/kg, kJ/kg | Btu/lb, ft lbf/lb |

| Specific Enthalpy of Saturated Ice | J/kg, kJ/kg | Btu/lb, ft lbf/lb |

| Specific Enthalpy of Water Vapor | J/kg, kJ/kg | Btu/lb, ft lbf/lb |

| Specific Entropy of Dry Air | J/(kg·K), kJ/(kg·K) | Btu/(lb·°R), ft lbf/ (lb·°R) |

| Specific Entropy of Humid Air | J/(kg·K), kJ/(kg·K) | Btu/(lb·°R), ft lbf/ (lb·°R) |

| Specific Entropy of Saturated Water | J/(kg·K), kJ/(kg·K) | Btu/(lb·°R), ft lbf/ (lb·°R) |

| Specific Entropy of Saturated Ice | J/(kg·K), kJ/(kg·K) | Btu/(lb·°R), ft lbf/ (lb·°R) |

| Specific Entropy of Water Vapor | J/(kg·K), kJ/(kg·K) | Btu/(lb·°R), ft lbf/ (lb·°R) |

| Specific Internal Energy of Dry Air | J/kg, kJ/kg | Btu/lb, ft lbf/lb |

| Specific Internal Energy of Humid Air | J/kg, kJ/kg | Btu/lb, ft lbf/lb |

| Specific Isobaric Heat Capacity of Humid Air | kJ/(kg·K) | Btu/(lb·°R) |

| Compressibility of Humid Air | [-] | [-] |

REQUEST EVALUATION DEMO

Please fill out the following form to request an evaluation demo version of CT-Mechanical 2.0 (64-bit).

Once you have submitted the form, your request will be processed by our team and an email will be sent to the address provided.

Notice

This website or its third-party tools use cookies, which are necessary to its functioning and required to achieve the purposes illustrated in the cookie policy. By closing this banner, scrolling this page, clicking a link or continuing to browse otherwise, you agree to the use of cookies. Please refer to our Cookie Policy, revised Privacy Policy and Terms and Conditions.